Biofouling is the uncontrolled growth of organic matter in a technical environment. Biofouling develops on existing biofilm and spread the biomass with the fluid downstream.

What is biofouling?

Biofilms form at interfaces. Like the interface at the water surface, where water and air meet. Or as described here on this page, at the water / pipeline interfaces. Biofilms are usually gelatinous, slimy films of microorganisms. If mature biofilm formations can develop undisturbed in a pipe or a system, it soon will spread in all directions. Horizontal along the pipe, vertical in the height. Plateaus are forming. If such plateaus reach a certain height, parts of the biomass are torn off by the current. And then transported with the water in flow direction. This is called biofouling.

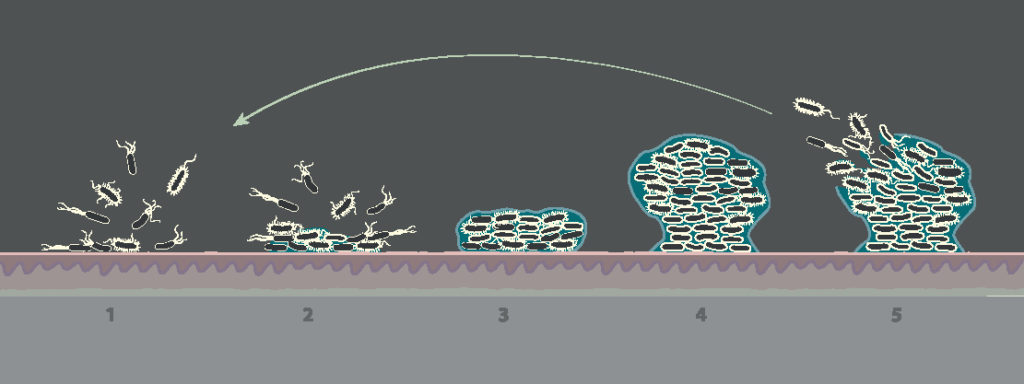

The illustration shows very clearly how this process takes place.

First, some microorganisms like bacteria accumulate (1). They become more (2) and then form a protective film (3). This protective film protect bacteria from chemicals or heat. The bacteria continue to grow into a plateau(4). When the plateau becomes too big, it bursts (5) and sprays the micoroorganism and bacterial occupants in all directions. When the water flows, the bacteria move with it and spread in the direction of flow. This is an endless process of biofilm formation, as long as the environmental parameters and the nutrition of the microbial organism are right.

The biofilm structure are mostly gelatinous, glue-like, slimy films of microorganisms. It might be bacterial cells or other microbial organism. Sometimes the bacterium living in the biofilm formation are pathogen as for instance legionella, but in most cases not.

We talk in this article not about biofilm infections. These are caused by bacterial biofilms in catheters or other medical devices. This is an issue in the medicine, but Merus concentrates on water systems only. Even if technical speaking, these two things are be related. As both are pipes, a catheter and a water line.

Biofilm in water lines

If mature bacterial biofilm can develop undisturbed in a pipe or a water system, it soon will spread in all directions. Horizontal along the pipe, vertical in the height. Plateus are forming. If such plateaus reach a certain height, parts of the biomass are torn off by the current. And then transported with the water in flow direction. This torn parts of the biofouling settle somewhere else in the water system and start a new biofilm formation.

Biofilm formations are not only found in drinking water, but increasingly in technically water used in the industry or agriculture. This means in cooling circuits, cooling towers, heat exchangers, water tanks or water lines for drip irrigation. Bacterial biofilms even occur in water used for production. Having microbiological contamunation in food or beverage, is not acceptable.

The higher the requirements on the purity of the water, the higher the effort to avoid such biofilms or at least to control them.

It is one thing to have biofilm in a cooling tower, this can be handled. But having biofilm in the process equipment of a pharmaceutical company is really serious.

We also are confronted with cases where the biofilm contained microorganisms, which released very aggressive secretions. These in turn led to considerable corrosion damage in the system. This phenomena is called MIC – Microbiological Induced Corrosion.

Technically it can become problematic if whole „plates“ of biofilm are loosened and pressed through the pipe. This can result in a plug that can lead to blockages in tight places in the system. Like blocking on valves or the inlet of a heat exchanger.

Or even lead to the formation of biofilm and biofouling in parts of the system that have not been contaminated since.

Solution against biofilm formation

In order to remove already existing biofilms, the classic method is heat or acid treatment. However, this is very complex and therefore expensive. One of the main problems with classical rehabilitation is to ensure that all areas of the pipe network are flushed. As explained above, this is very difficult to impossible.

As an example, if you have to make heat sanitisation in a hospital or hotel, you have to ensure that no guest is using the tap point during this sanitisation. To ensure to kill biofilm bacteria the water has to have minimum 60°C. If you want to reach 60°C on the 10th floor of a building, the water at the boiler in the basement usually needs to be more than 80°C.

However, if not all microorganisms are killed during this remediation, biofilm formation will resume after a short time.

Merus against biofouling

Merus has developed special bio rings for the treatment of different biofilm composition. With these Bio Rings we can achieve very good results in infested systems. These Bio Rings makes it very difficult for bacteria to settle at surfaces, the biofilm formation is hardly possible. If there is no biofilm formation, thers is no biofouling either. The mode of action is to be compared with that against the legionella, or how we treat marine growth. However, the removal of the biofilm is even more demanding. This is mainly due to the fact that the bacterium or other microorganism living in it have developed strategies for self-protection.

This slimy film, for example, offers good protection against thermal remediation. Some spores are even more resistant to heat than the bacterium itself. This means that problems with a biofilm struktur cannot be solved overnight. With the Merus Ring we can prevent the biofilm even in sewage systems.

Today, we have numerous applications in which the biofilm has been minimized so that it no longer causes any problems. In some applications the biofilm was even completely removed.

Even if the chemical dosage has been completely discontinued, the results obtained are very stable and satisfactory. Long-term results and measurements also speak for us. Some projects show excellent and stable results for more than ten years.

Before – After comparison

The photo to the right shows a piece of pipe cut lengthwise. The Merus Ring was previously installed in the middle of this pipe section. The left section shows many small and medium white dots. In the middle, where the ring was installed, there is almost no biofilm. And in the right section which is down stream the ring there are even fewer, smaller dots. Here we showed a direct relation of how Merus Ring affect the biofilm development.

Unfortunately, the complete system is not biofilm-free in this application. In untreated sections, the bacteria can continue to grow undisturbed. In very large systems, the range of effect is limited. This means that the entire piping system must be equipped with multiple Merus Bio-Rings to fully control the biofilm-forming.

If only one Merus Bio Ring is installed on a pipe string, the spread is only restricted. It is also difficult if the feed water is contaminated.

However, the biggest advantage is still that the Merus oscillations spread even in stagnant water. This means that they also reach the dead legs*. It is precisely in these pipeline sections that the biofilm usually settles undisturbed.