Merus avoids fouling, scaling and corrosion in heat exchanger

There are several parameters in a heat exchanger that are responsible for the formation of deposits. For example, raw water with high TDS or other impurities is most likely to cause deposits on the tubes or plates. These deposits reduce the flow rate and, consequently, the heat transfer. This in turn requires maintenance and cleaning of the heat exchanger.

Therefore, the parameters that can be influenced are important for us at Merus. The focus is on the solubility of the substances in the liquids. Salts are usually soluble in a liquid, but sand, silt or sludge are not. This means that the improvements achieved are better when the deposits in the heat exchangers are soluble in water.

A clean heat exchanger does not need to be cleaned !

When we treat just one single heat exchanger, we install a Merus ring in the inlet of the side to be treated. Sometimes we even install on both sides, the tube side and the shell side. In this way, we have significantly better performance in critical applications.

In fact, foreign substances in the water settle much less when using Merus Rings than before. This is because they are flushed through the heat exchanger tubes usual without forming deposits.This keeps the surfaces clean and also prevents biofilm, bacteria and other organisms from taking hold. Ultimately, this means that clogged tubes, as seen in the photo, are no longer an issue.

The time between each heat exchanger services are much longer. And cleaning a heat exchanger is very easy, because there are no hard crusts on the plates / tubes. Maintenance can in many cases be reduced from once a month to once a quarter or even once a year.

Marine heat exchanger cleaning

In marine installations, be it on a boat, a ship or an offshore platform, the highest requirements are placed on Merus rings. The raw water is seawater holding salt and calcium. Causing fouling, corrosion and beyond that even sea life, like barnacles or mussels.

We have installations on fresh water generators, which is a modified plate heat exchanger. First we removed the existing scale and flushed it out together with the brine. Since then, the installation remains clean, no need for chemical cleaning.

Reduction of service effort - verifiable case

Over 25 long years we are improving the efficiency of heat exchangers. We keep of course track of the improvements. Some of the used data are from the evaluation period after the installation. Majority of the data are from big projects, where we are until today regularily in contact with the customer and control the situation at the heat exchanger. Using parameters such as the pressure drop (delta P) or the heattransfer.

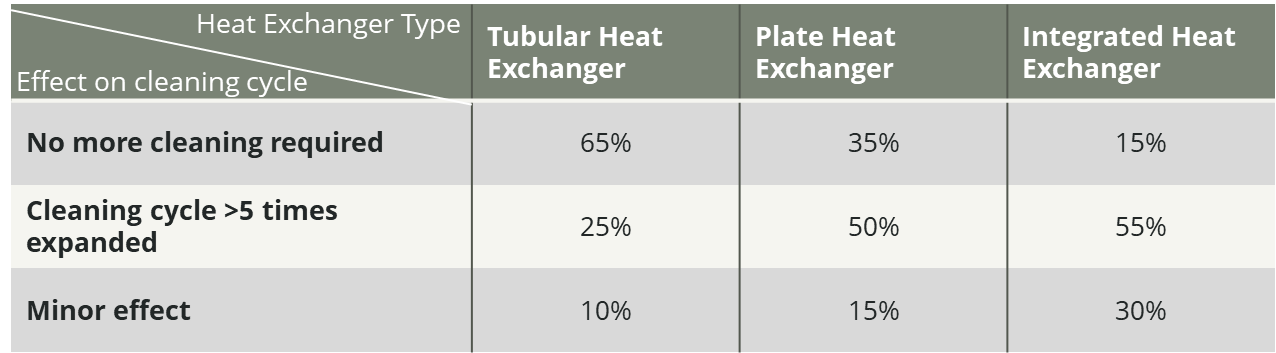

In the table below you see the approximate result of heat exchangers, where we are treating the water side. These results where achieved in a system where the cooling water had not more than 3000 TDS. Also the substances causing the fouling are soluble in the water.

We will discuss the expected results with the customer before the installation. To get control of Biofouling, it might not be enough to treat only the heat exchanger. One have to look on the cooling system as a whole. If we provide treating of the product side, things are far more difficult. See also fouling in an oil application.

Water Treatment for Heat Exchanger and Cooling Loop

Heat exchangers are very often connected to a cooling circuit. Therefore, they should not be treated as two separate systems, but as one unit.

With Merus technology we treat the water, not the equipment. Therefore, the connection between the heat exchanger and the cooling (tower), for example in an air conditioning system, can be important to identify and locate the problem. If the cooling tower is full of algae and biofilm, this may indicate that there could also be a problem in the heat exchanger.